Joining and welding

Joining with precision – from individual components to joints fit for series production

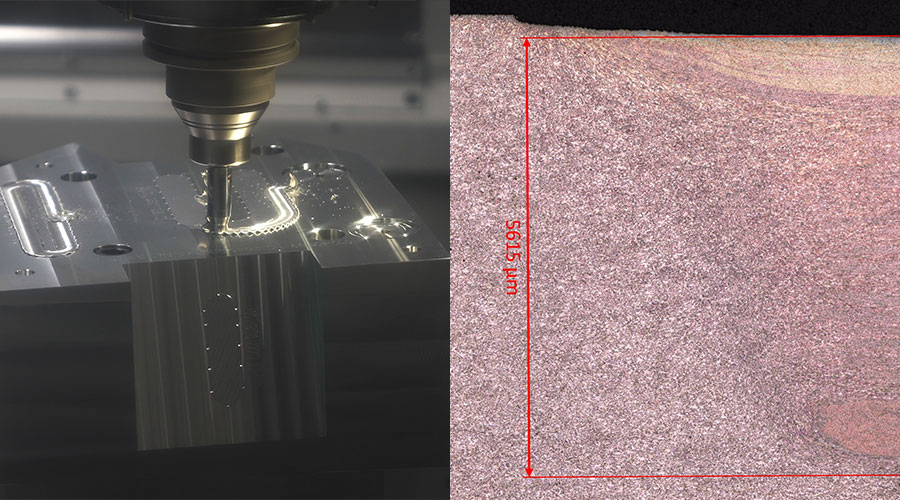

Friction stir welding

Friction stir welding (FSW) involves using pressure to insert a rotating tool into the joint. The resulting frictional heat makes the material ductile without melting it, allowing a strong, firmly bonded joint to be created. Joints produced using this method are of exceptional quality and are very robust, making them ideal for aluminium and other light metals.

Benefits:

- Joints are extremely strong and generally more stable than joints produced using conventional welding methods

- Joints are reliable, tight and even impermeable to helium

- There is no need for additional materials, such as welding wire or shielding gas

- Components are joined in a plastic state, keeping shrinkage, cracks and pore formation to a minimum

- The method conserves resources, is energy efficient and low in emissions

- The reproducible quality is ideal for automated series production

Materials:

- Aluminium alloys

- Copper alloys

- Mixed joints are possible

Tungsten inert gas welding

Tungsten inert gas (TIG) welding involves striking an electric arc between a non-consumable tungsten electrode and the workpiece. Depending on the requirements, the welding can be performed with or without a filler material. The method can be used to create precise, clean and spatter-free welded joints and is ideal for producing high-quality visible joints and for joining challenging materials.

Benefits:

- Produces clean, smooth and precise welded joints of outstanding quality

- The method is universally applicable, making it suitable for virtually all metals and material thicknesses

- The spatter-free processing makes it ideal for visible joints

- Heat and energy can be applied precisely, even in challenging areas of use

- The welded joints are durable, very strong and highly resistant to corrosion

Materials:

- Suitable for most steel alloys

- Nickel-based alloys

- Aluminium alloys

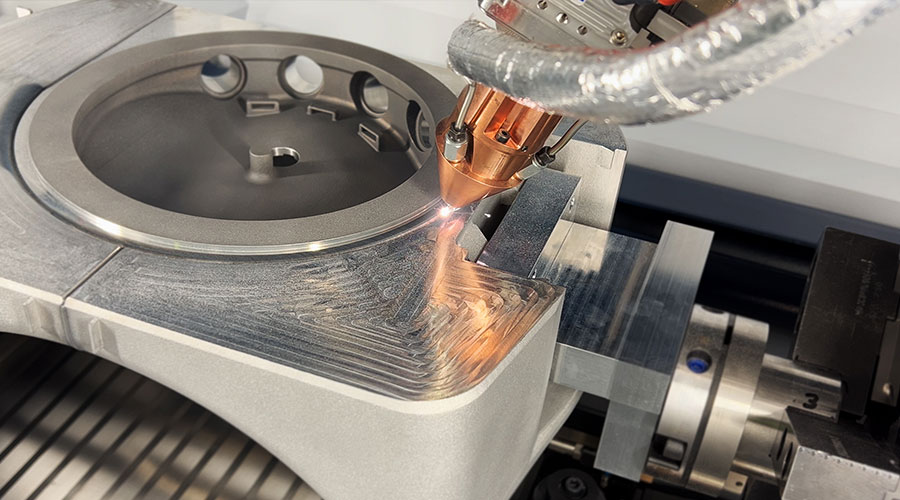

Laser metal deposition (DED - LMD)

In direct energy deposition (DED) or laser metal deposition (LMD), a highly focused laser beam melts the surface of the workpiece with pinpoint precision, while metal powder is deposited onto the surface at the same time. The method can be used to manufacture joints, to coat surfaces or to repair components – with minimal heat and maximum precision.

Benefits:

- Highest level of precision for creating fine joints with control

- Building up material by adding powder allows repairs to be performed and material to be deposited layer by layer exactly where it is required

- Low heat requirements result in minimal deformation and excellent surface quality

- The highly automated process is ideal for state-of-the-art series production lines and robotics with high reproducibility

- The method is versatile and can be used for a wide range of metals and complex geometries

Materials:

- Suitable for most steel alloys

- Nickel-based alloys

- Aluminium alloys

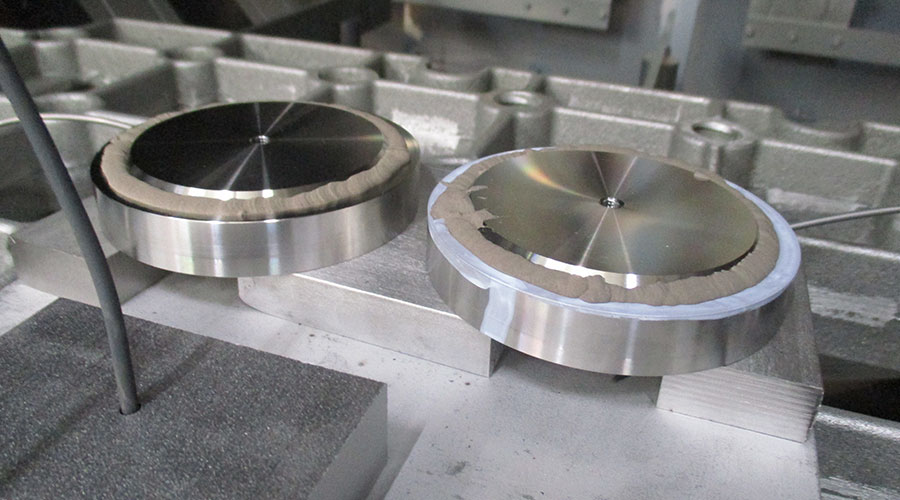

Vacuum brazing

In vacuum brazing, the components are heated evenly in a furnace under a vacuum until the filler melts and the joints are completely covered by molten filler. The method produces clean, oxide-free, impermeable joints without any flux residue, making it ideal for complex or sensitive components.

Benefits:

- Brazed joints are clean, oxide free, very strong and impermeable

- The method is suitable for complex geometries, where there are many joints and for areas that are difficult to access

- Brazing produces high-quality joints with smooth surfaces without any flux residue

- The material is treated gently by being heated evenly with minimal deformation

- The results are reliable and reproducible, including on series production lines

Materials:

- Stainless steel alloys

- Copper alloys

- Combinations of stainless steel and copper

- Other material combinations are possible

Uncover your potential for innovation.

Your Pace makers for joining and welding

As your research and development partner, we can help you explore new avenues of business and market opportunities. Find out more about our unique consulting and manufacturing standard for precision parts.

Challenge us to help you with your projects today!

Phone +49 9172 6956-0

Christoph Barth

Materials Technician AM / International Welding Engineer (IWE)