Initial Situation:

High-efficiency electrolytic cells with a long lifespan are needed for hydrogen to be produced cost-effectively and in sufficient volume for the climate-neutral transformation of industry and transport. Thanks to their favourable load-change behaviour and high current density, cells based on polymer electrolyte membranes (PEM) are particularly suitable for meeting these requirements. The bipolar plate (BPP) and the porous transport layer (PTL), which connects the BPP to the membrane, facilitate the supply of media in the cell. The layered structure of these multi-component cell parts limits optimisation in terms of the thermal and electrical connections, the transport of material and sustainable manufacturing. The project will develop a range of structure designs for the intended application to increase the efficiency and lifespan of the cells and simplify the assembly process. Investigations will also be conducted into de-powdering the structures developed with the aim of overcoming the current hurdles faced during additive manufacturing in the production and finishing stages, in particular in terms of de-powdering.

Goals:

The overall aim of the project is to enhance the cell efficiency and lifespan of electrolytic cell systems by using additive manufacturing to design and manufacture key cell components so that they are consistently optimised for their specific function. Optimising the design of the bipolar plate (BPP) and porous transport layer (PTL) has significant potential. By manufacturing these components as an integrated, fully metallic part, it is possible to eliminate the root cause of efficiency- and lifespan-limiting effects (e.g. contact resistances within the cell) in the current component structure in a targeted way and significantly simplify the cell assembly process. At present, the supply chain includes a large number of manufacturers and suppliers of the individual components. Integrating the various cell components into one optimised overall structure will simplify and shorten the supply chain significantly. In the long term, it will also be possible to apply this approach to other galvanic cells (e.g. fuel cells) to increase their efficiency and lifespan, while also simplifying their assembly process.

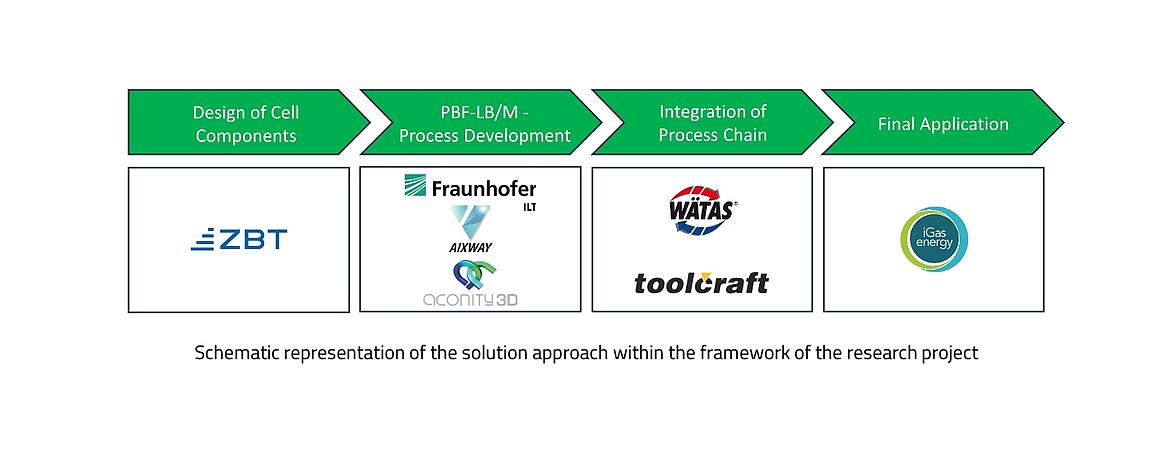

Process:

Drawing on the basic proof of functionality of the newly developed cell components, the planned project will follow a holistic approach to allow a complete electrolysis system to be tested in a relevant environment. WP1 (work package 1) will define the requirements for the components and manufacturing processes in a specification. The iterative development cycle will then begin. On that basis, WP3 and WP4 will develop the manufacturing process and required finishing processes and test them on the newly designed components. WP5 will test and analyse the finished components, providing the input for a further iteration loop. The outcome of this process will be the optimised design of the additively manufactured system and the processes required for the design. Finally, WP6 will involve manufacturing and characterising a demonstrator on an industrial scale.