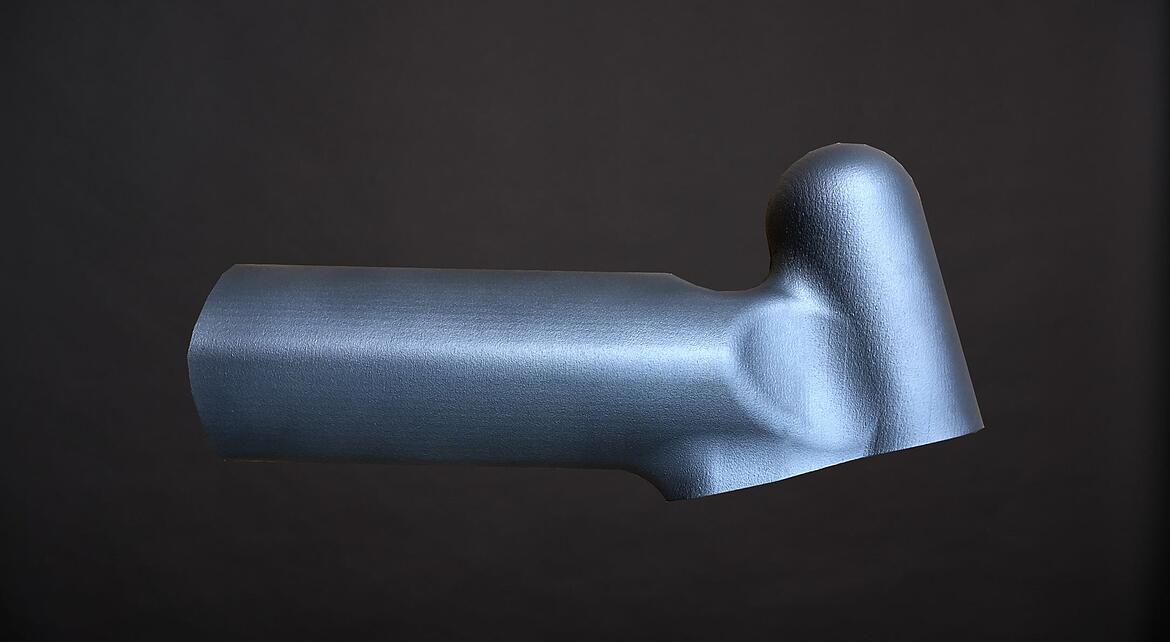

Based in the German town of Tuttlingen, Aesculap AG is part of the B. Braun Group and provides products and services to the medical engineering and pharmaceutical industries. As a leading supplier of motor systems, Aesculap sells products for use in various areas of medicine, such as orthopaedics, traumatology, heart surgery and dermatology. One such example is its battery-operated motor system Acculan. The device has a longer service life and is more reliable when there is no need for its battery to be sterilised. To ensure that this is the case, it is imperative that the battery does not come into contact with the device’s sterile exterior. To produce the battery casing for this motor system, toolcraft used additive manufacturing.

Customer:

Aesculap AG

www.bbraun.com

The starting point:

Production waste caused by unwanted cavities

The motor system’s round, ergonomic handle was originally manufactured using centrifugal casting. However, this process is generally unable to guarantee that the component has a uniform thickness all the way around. Another common problem is shrinkage, which causes small cavities to form during production. This can lead to surface defects developing during post-processing, making the component unusable.

The challenge:

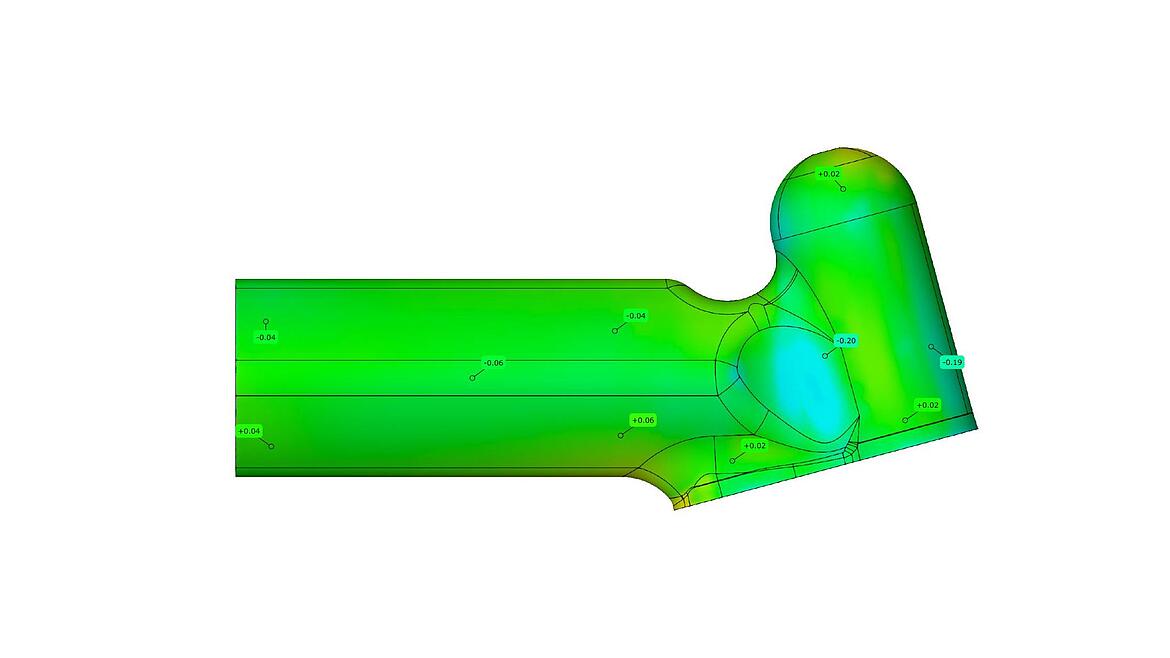

No tension or warpage

Steps were taken to refine the component’s geometry even before the additive manufacturing process began. This involved using warpage simulation to ensure that any tension or warpage could be eliminated or reduced. Another aim was to lower costs in the long term by increasing geometric fidelity and keeping production waste to a minimum. This also reduces the need for post-processing, e.g. milling, and keeps the production of additional holding devices to a minimum, lowering costs further.

The Approach:

Warpage simulation

- Use of the entire additive manufacturing process chain and widespread application of the software Siemens NX, from design and simulation to 3D metal printing and quality control (optical and non-destructive)

- Material: titanium alloy TiAl6V4

- Warpage simulation calculation to ensure the exact target geometry is achieved

The Results:

Precise results

The additively manufactured parts passed the stress test and therefore compared favourably with the existing cast components. Precision was improved and unwanted cavities were no longer formed, reducing the need for mechanical reworking. Since additive manufacturing is a very economical way of producing bespoke small batches of parts, it would, for example, be possible to make handles in different shapes and sizes.